Stainless steel tubes are a popular choice in various industries due to their durability, corrosion resistance, and versatility. With the wide range of applications for stainless steel tubes, it is essential to understand the basic types and factors to consider when selecting the right one for your needs. In this article, we will explore the different types of stainless steel tubes available in the market, discussing their unique properties and applications. Additionally, we will delve into the key factors that should be taken into account when choosing stainless steel tubes, such as the intended use, environment, and budget. By understanding the basic types and considering the important factors, you can make an informed decision and ensure that you select the most suitable stainless steel tube for your specific requirements.

Whether you are in the construction, automotive, or manufacturing industry, this article will provide you with valuable insights to help you make the right choice when it comes to stainless steel tubes.

Types of Stainless Steel Tubes

Stainless steel tubes are widely used in various industries for their exceptional strength, durability, and corrosion resistance. There are different types of stainless steel tubes available in the market, each with its own unique properties and applications.

One of the most common types of stainless steel tubes is austenitic stainless steel. This type of tube is highly resistant to corrosion and can withstand high temperatures. It is commonly used in industries such as food processing, pharmaceuticals, and chemical processing. Austenitic stainless steel tubes are also known for their excellent formability and weldability, making them easy to work with during fabrication.

Another type of stainless steel tube is ferritic stainless steel. This type of tube has a higher chromium content, which provides it with good resistance to corrosion and oxidation. Ferritic stainless steel tubes are often used in applications where high strength and resistance to stress corrosion cracking are required, such as in automotive exhaust systems and heat exchangers.

Martensitic stainless steel tubes are another type that is known for their high strength and hardness. These tubes are commonly used in applications that require wear resistance, such as in cutlery, surgical instruments, and turbine blades. Martensitic stainless steel tubes are also magnetic, which makes them suitable for applications in the electronics industry.

Duplex stainless steel tubes are a combination of austenitic and ferritic stainless steels. These tubes offer a unique combination of high strength and corrosion resistance, making them ideal for applications in harsh environments, such as offshore oil and gas platforms. Duplex stainless steel tubes also have good weldability and formability, making them versatile in various industries.

Factors to Consider When Choosing Stainless Steel Tubes

When it comes to choosing stainless steel tubes, there are several factors that need to be considered. Stainless steel tubes are widely used in various industries due to their durability, corrosion resistance, and ability to withstand high temperatures. However, not all stainless steel tubes are created equal, and it is important to understand the key factors to consider before making a decision.

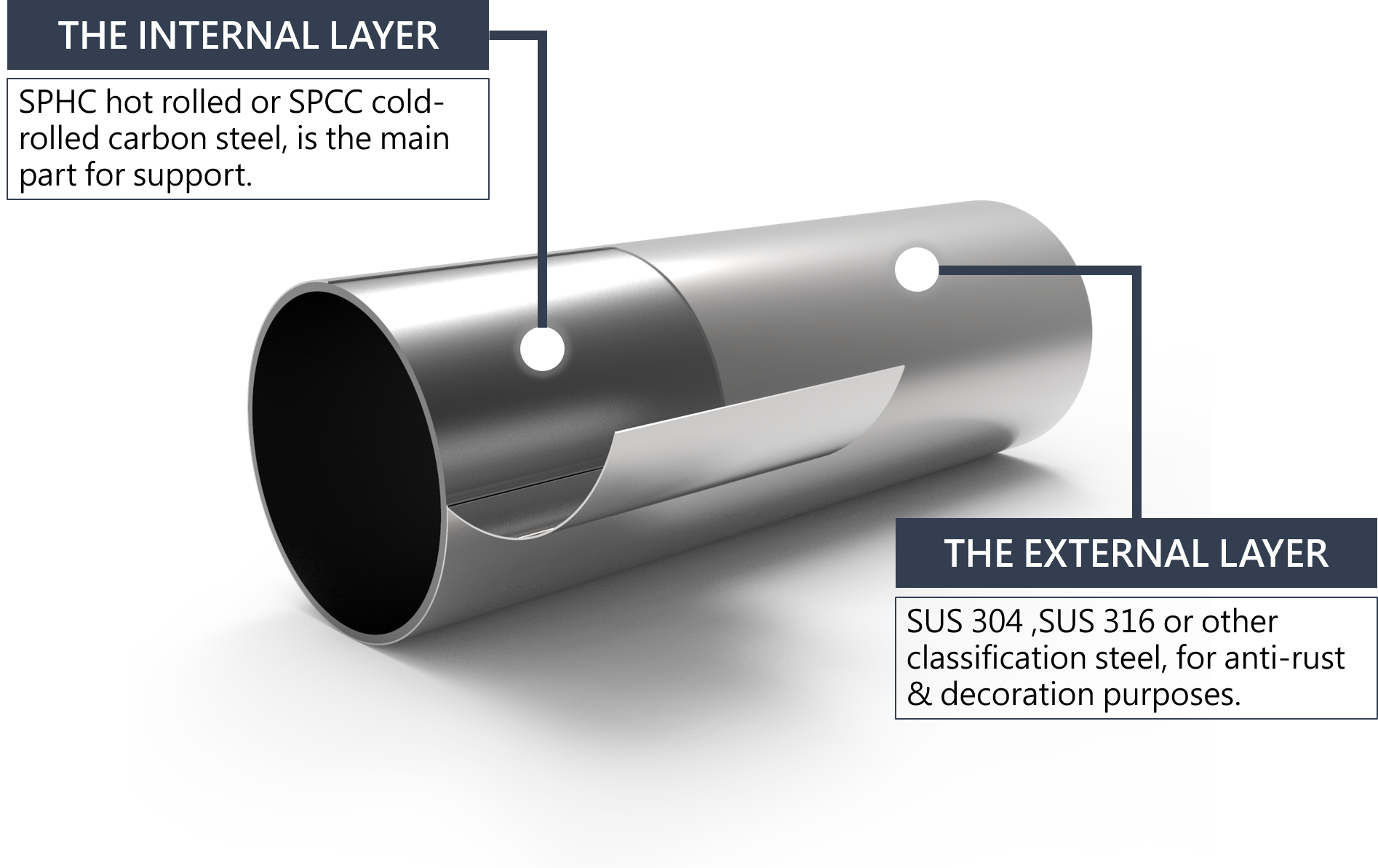

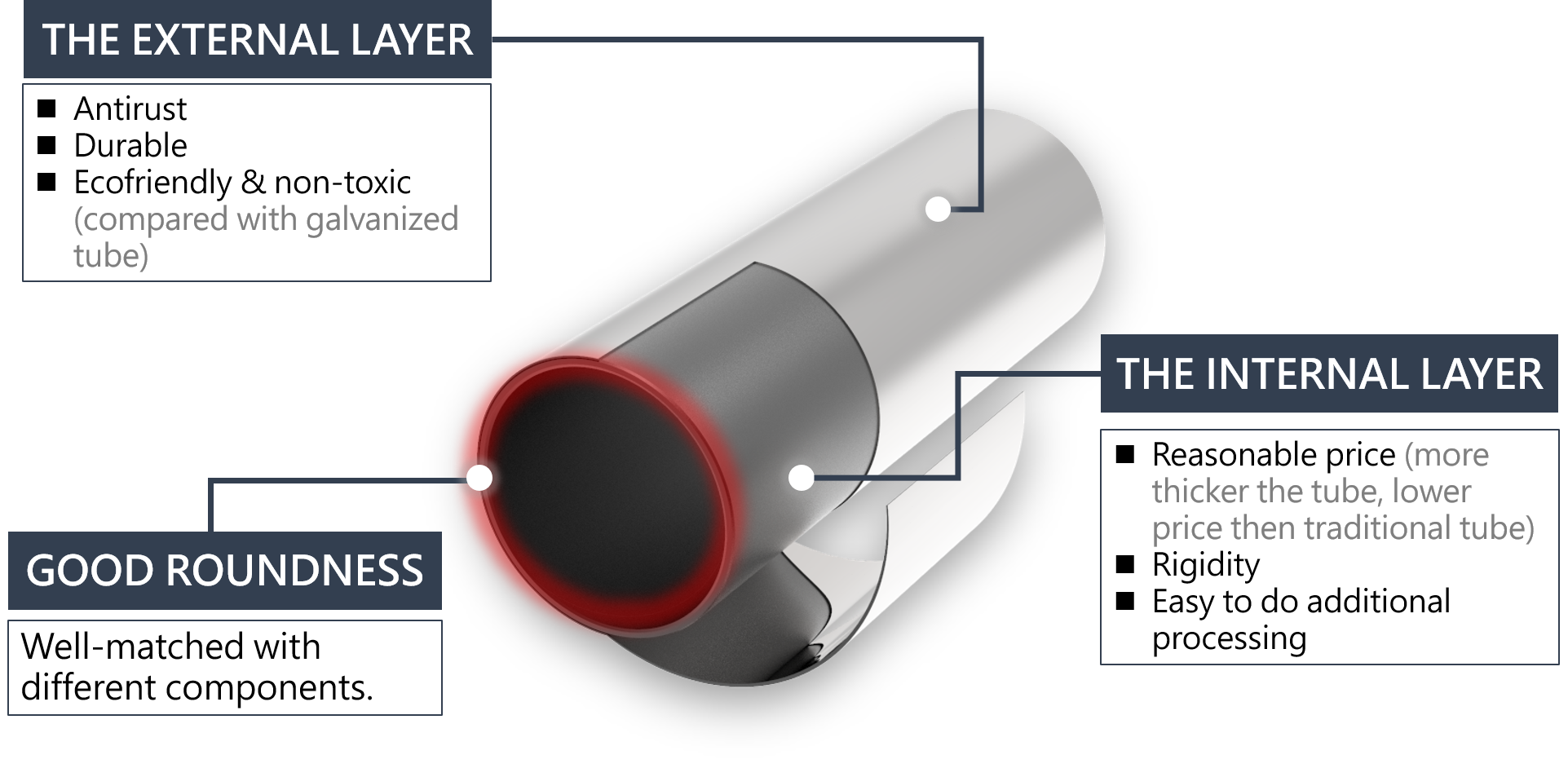

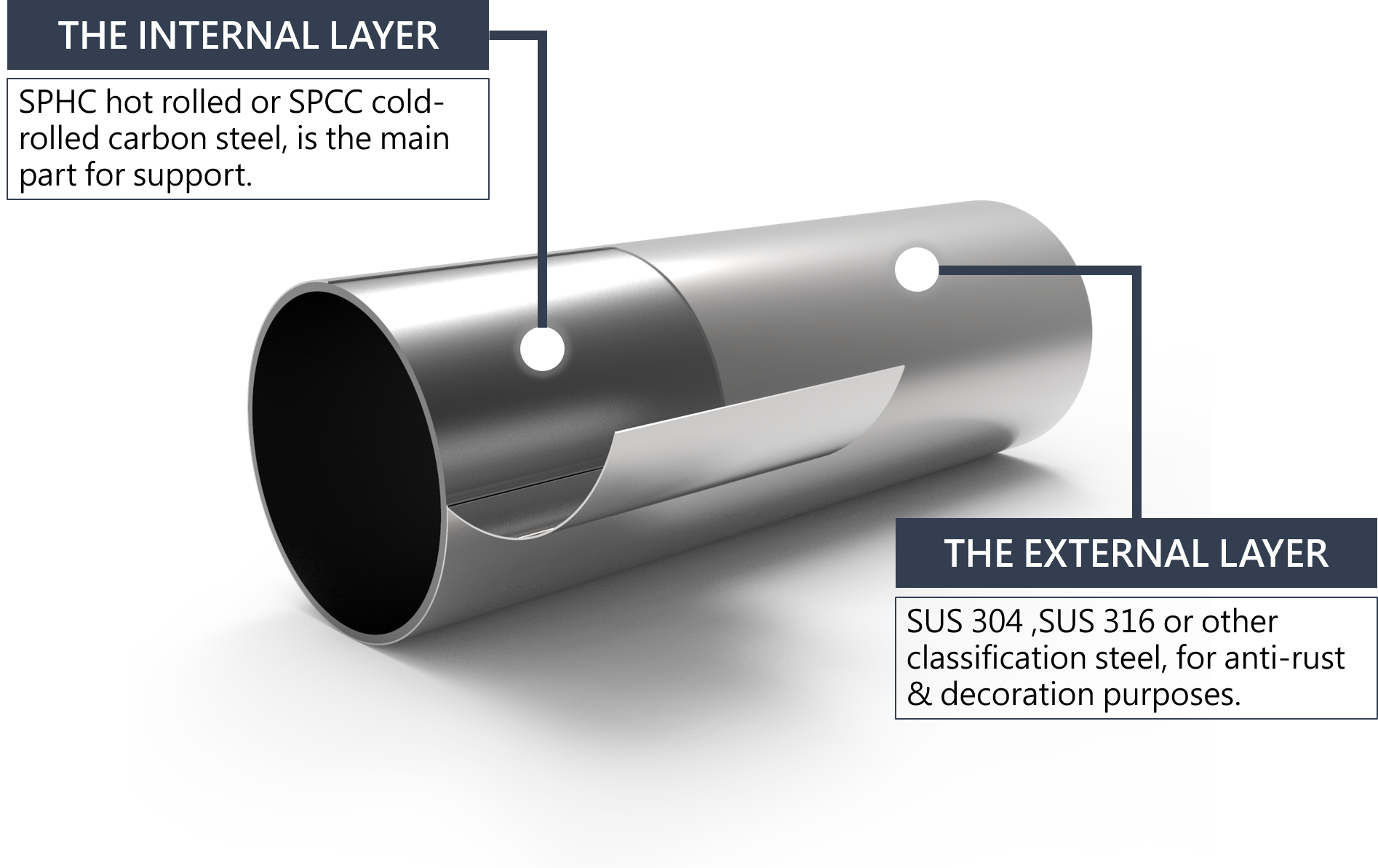

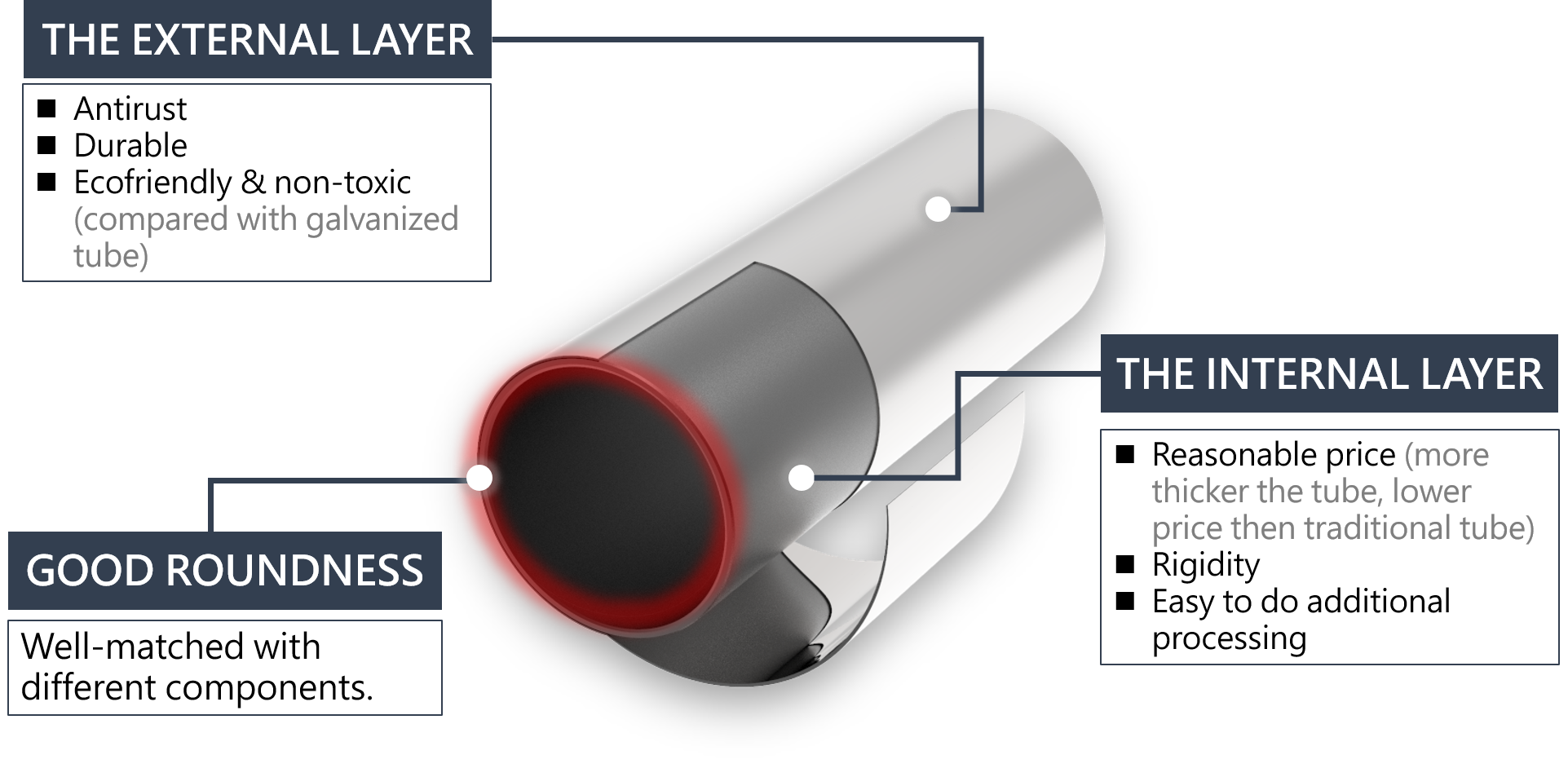

One of the first factors to consider is the grade of stainless steel. Stainless steel is available in different grades, each with its own unique properties. The most common grades used for stainless steel tubes are 304 and 316. Grade 304 is a versatile and cost-effective option, while grade 316 offers superior corrosion resistance, making it ideal for applications in harsh environments or where the tube will come into contact with corrosive substances.

Another important factor to consider is the size and dimensions of the stainless steel tube. The size of the tube will depend on the specific application and the flow requirements. It is crucial to choose the right size to ensure optimal performance and efficiency. Additionally, the dimensions of the tube, such as the wall thickness and diameter, need to be carefully considered to meet the requirements of the intended use.

The next factor to consider is the finish of the stainless steel tube. The finish not only affects the appearance of the tube but also its resistance to corrosion. Common finishes for stainless steel tubes include brushed, polished, and mill finishes. The choice of finish will depend on the aesthetic preferences as well as the environmental conditions the tube will be exposed to.

In addition to the grade, size, and finish, it is important to consider the manufacturing process and quality standards of the stainless steel tubes. Look for tubes that are manufactured using advanced technologies and adhere to industry standards to ensure the highest quality and performance. This includes factors such as the welding process, heat treatment, and inspection procedures.

Finally, it is crucial to consider the cost and availability of the stainless steel tubes. While quality is paramount, it is also important to find a balance between quality and cost-effective solutions. Consider sourcing stainless steel tubes from reputable suppliers who offer competitive pricing and have a reliable supply chain.

Conclusion

Stainless steel tubes are available in various types with different properties and applications. They are popular in various industries due to their versatility and durability. When choosing stainless steel tubes, factors such as grade, size, finish, manufacturing process, and cost should be considered to ensure that they meet specific needs and provide long-lasting performance.