Introduction

Stainless steel tubes are the ideal material for modern railing and handrail systems due to their excellent corrosion resistance, strength, and aesthetic appeal. This article will explore the application of stainless steel tubes in railing and handrail systems in detail, from the design phase to the installation process, providing a comprehensive analysis of their advantages and considerations.

Design Phase

Needs Analysis

Functional Requirements: Determine the primary functions of the railing and handrail system, such as safety protection and decorative aesthetics. For example, in high-rise residential buildings, safety is the primary consideration, while in commercial buildings, aesthetic design may be more important.

Environmental Factors: Consider the installation environment, such as indoor, outdoor, humid areas, coastal areas, etc., and choose the appropriate stainless steel material (e.g., 304 or 316 stainless steel). For instance, railing and handrail systems in seaside villas should use 316 stainless steel to resist salt spray corrosion.

Design Style

Modern Minimalism: Use simple lines and smooth stainless steel surfaces, suitable for modern architectural styles. For example, the balcony railing of a high-end apartment uses a combination of stainless steel tubes and glass, which is simple yet elegant.

Industrial Style: Combine rugged stainless steel tubes with other metal elements to create an industrial visual effect. For example, the staircase handrail in a creative office space uses a combination of stainless steel tubes and black steel plates, showcasing a strong industrial style.

Custom Design: Provide personalized designs based on customer needs to offer unique aesthetic effects. For example, the staircase handrail system in a luxury hotel uses stainless steel tubes and decorative carvings, exuding nobility and elegance.

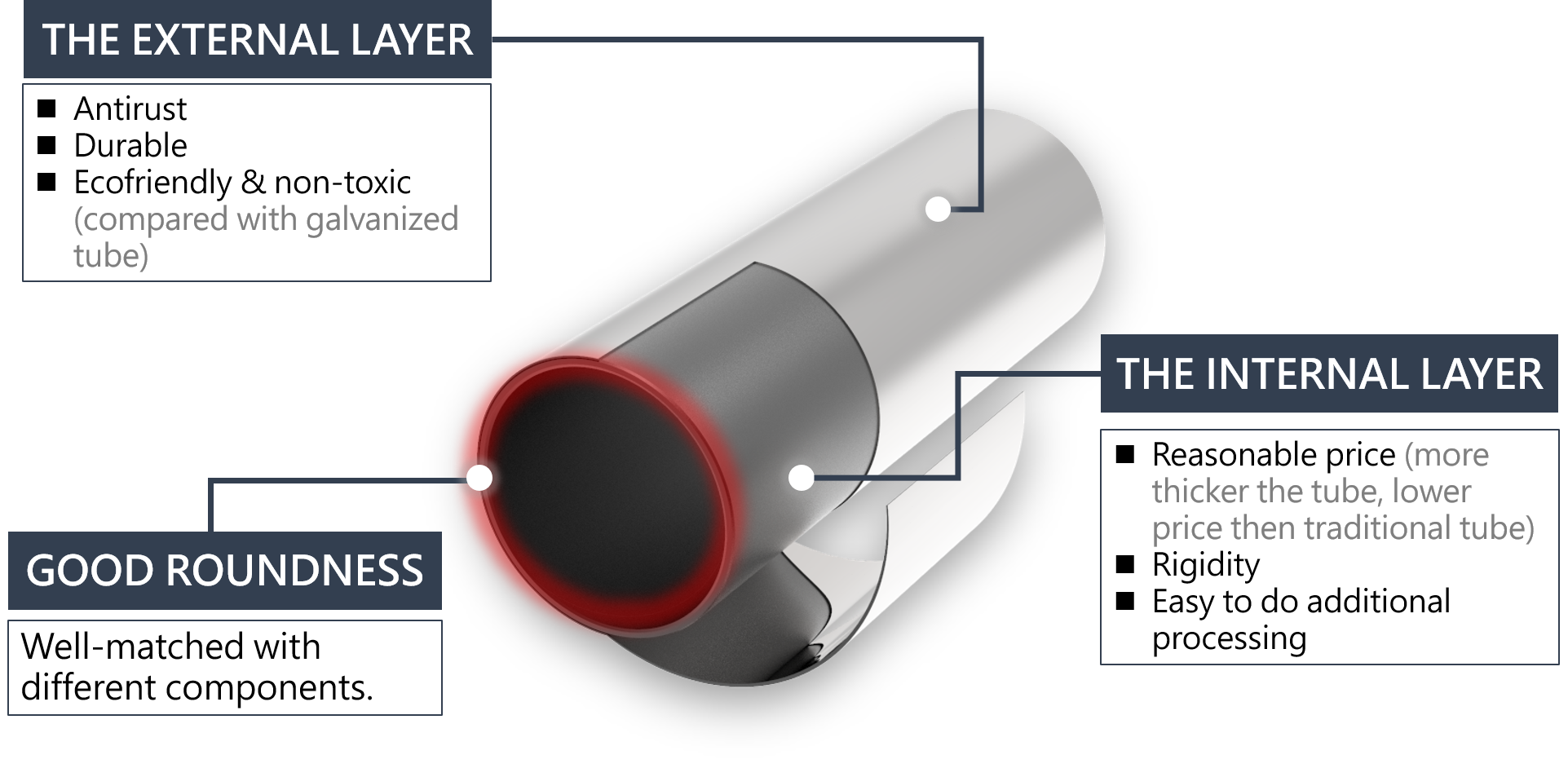

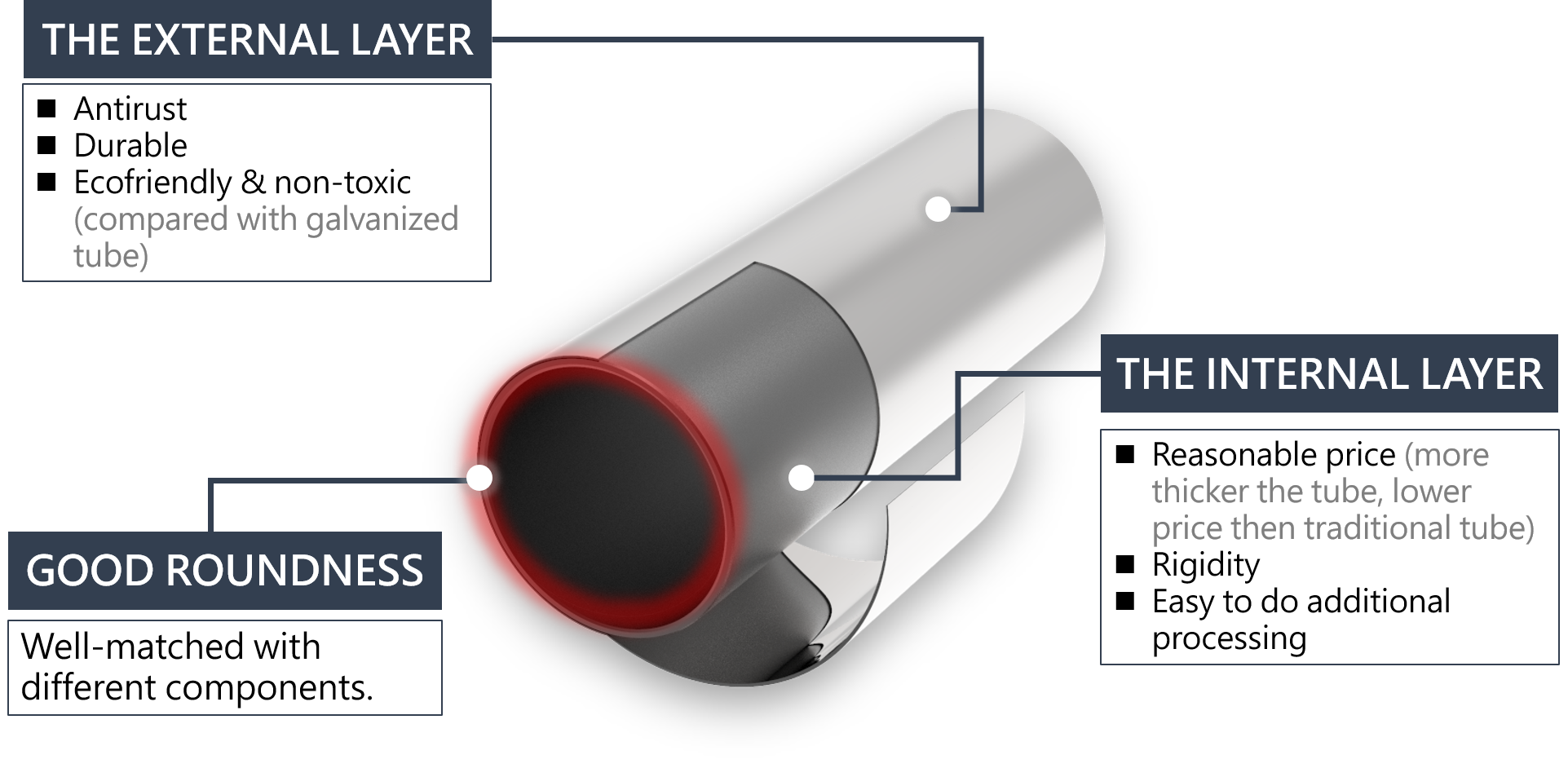

Dimensions and Specifications

Tube Diameter Selection: Choose the appropriate tube diameter based on the height of the railing and the usage scenario, with common specifications being Ø38mm, Ø42mm, Ø50mm, etc. For instance, handrail systems in shopping malls typically use Ø50mm stainless steel tubes to ensure sufficient strength and stability.

Wall Thickness Selection: Choose the appropriate wall thickness based on load-bearing requirements to ensure structural stability and safety. For example, railing systems in public facilities may require thicker walls to withstand high traffic usage environments.

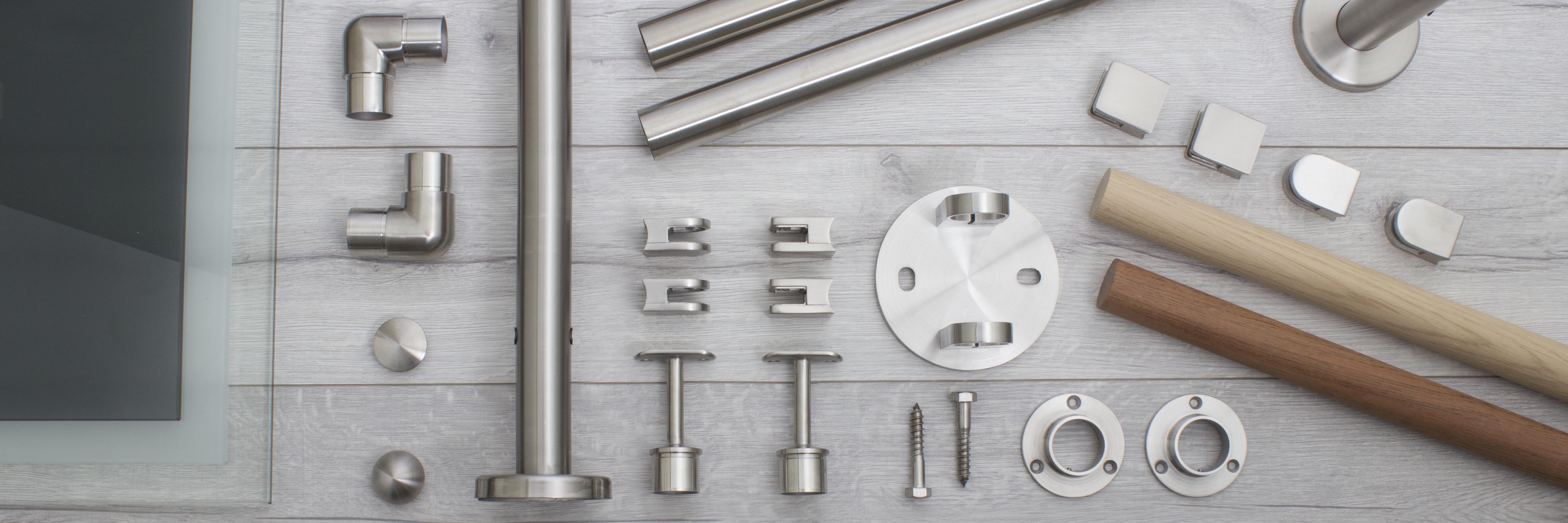

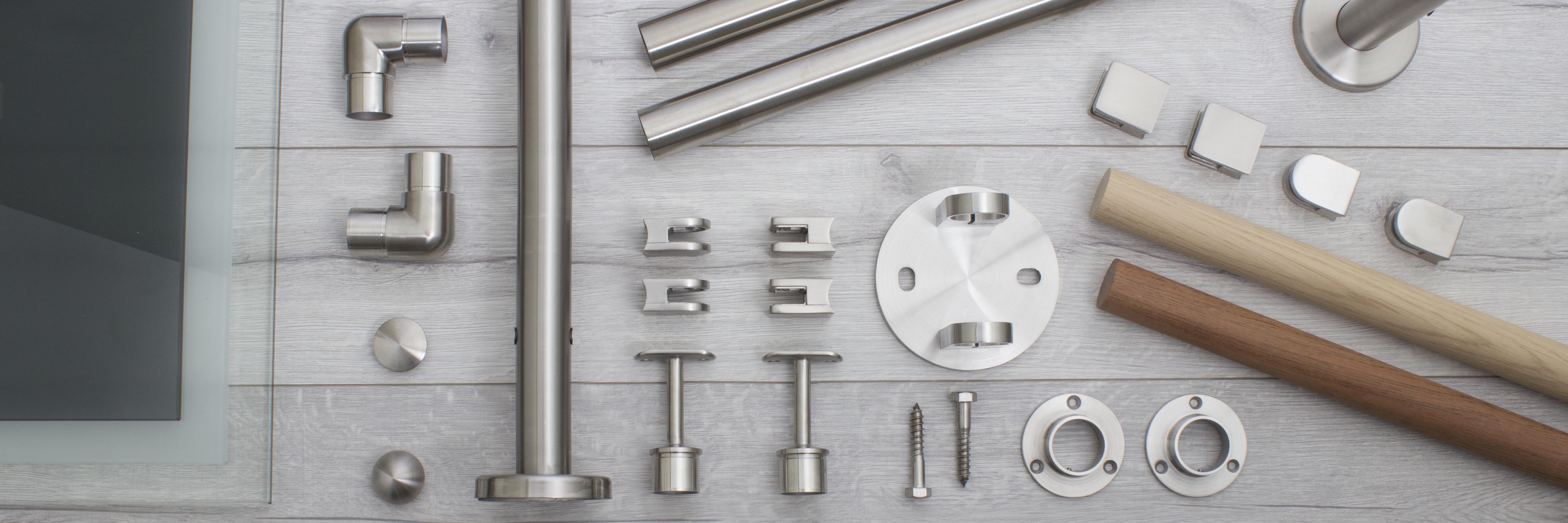

Accessory Selection

Connectors: Choose suitable connectors such as elbows, tees, and crosses to ensure firm connections between components. For instance, the railing system in a large shopping center uses high-strength stainless steel connectors to ensure system stability and safety.

Bases and Brackets: Choose suitable bases and brackets to provide stable support and fixation. For example, the handrail system in a subway station uses thickened stainless steel bases to provide additional stability.

Decorative Elements: Choose decorative elements such as end caps and decorative balls based on design needs to enhance overall aesthetics. For example, the balcony railing system in a luxury villa uses stainless steel decorative balls to add visual highlights.

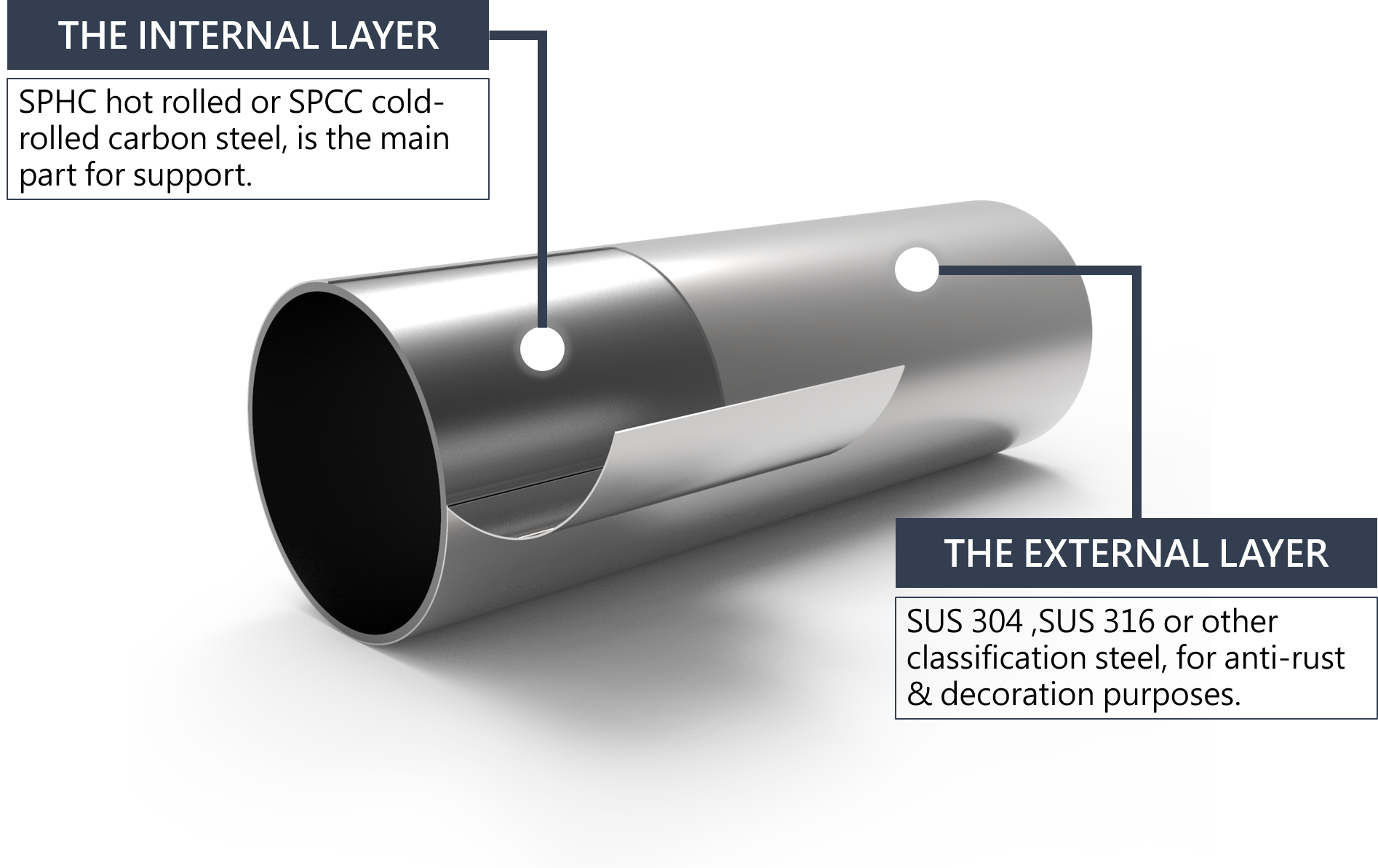

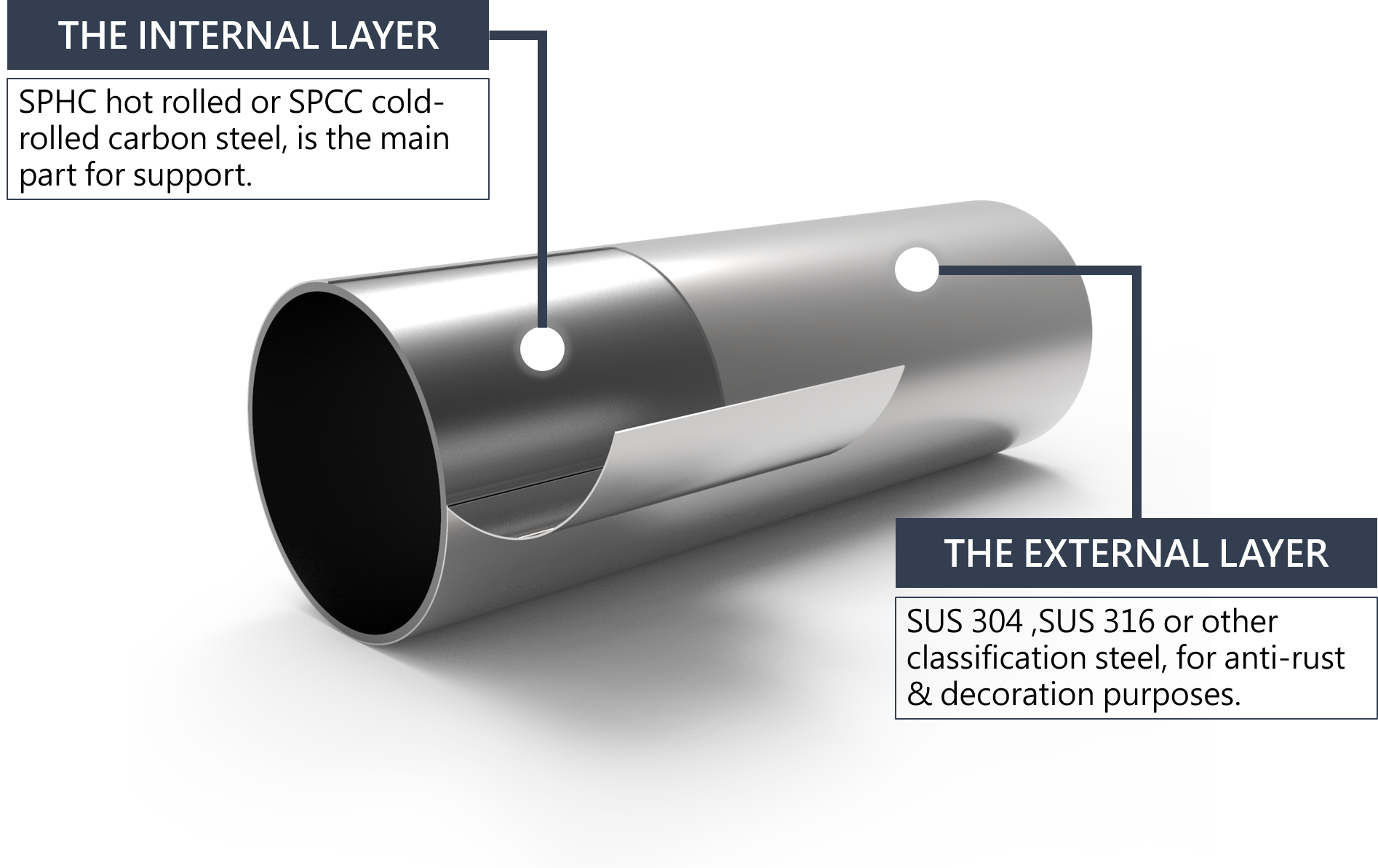

Material Selection

Stainless Steel Material

304 Stainless Steel: Suitable for most indoor and outdoor environments, offering good corrosion resistance and mechanical properties. For example, the indoor handrail system in an office building uses 304 stainless steel, which is both aesthetically pleasing and durable.

316 Stainless Steel: Contains molybdenum, providing superior corrosion resistance, especially suitable for coastal or chemical plant environments. For instance, the railing system in a seaside resort uses 316 stainless steel to withstand long-term salt corrosion.

Surface Treatment

Mirror Polishing: Provides a high-gloss surface effect, suitable for high-end venues. For example, the handrail system in a five-star hotel uses mirror polishing to showcase a luxurious texture.

Brushed Finish: Provides a matte effect, reducing the appearance of fingerprints and stains, suitable for public places. For instance, the handrail system in a shopping center uses a brushed finish, which is both aesthetically pleasing and easy to maintain.

Sandblasting: Provides a uniform matte surface, increasing friction, suitable for places with anti-slip requirements. For example, the handrail system in a sports stadium uses sandblasting to enhance safety.

Installation Process

Preparation Work

On-Site Measurement: Conduct detailed measurements of the installation site to ensure design dimensions match actual conditions. For example, the handrail system in a large shopping center underwent multiple precise measurements before installation to ensure every detail met design requirements.

Material Preparation: Prepare the necessary stainless steel tubes, accessories, and tools according to the design drawings. For instance, the handrail system in a high-rise residential building prepared all necessary materials and tools before installation to ensure a smooth installation process.

Embedded Parts Installation

Positioning and Drilling: Position and drill holes where the posts need to be installed to ensure accurate hole positions. For example, the railing system in a public square conducted detailed positioning and drilling before installation to ensure each post could be accurately installed.

Fixing Embedded Parts: Fix the embedded parts to the ground or wall to ensure they are firm and stable. For instance, the handrail system in a subway station used high-strength embedded parts to ensure system stability and safety.

Post Installation

Fixing Posts: Fix the stainless steel posts to the embedded parts to ensure the posts are vertical and stable. For example, the handrail system in a shopping center used professional tools during post installation to ensure each post was vertical and stable.

Height Adjustment: Adjust the post height according to design requirements to ensure all posts are of consistent height. For instance, the balcony railing system in a luxury villa underwent precise height adjustments during installation to ensure overall aesthetics.

Handrail Installation

Connecting Handrails: Connect the handrails to the posts using screws or welding to ensure firm connections. For example, the handrail system in an office building used high-strength screws during installation to ensure system stability.

Angle Adjustment: Adjust the handrail angle according to on-site conditions to ensure the handrails are straight. For instance, the handrail system in a public facility underwent multiple angle adjustments during installation to ensure each handrail was straight and aesthetically pleasing.

Accessory Installation

Installing Connectors: Install connectors such as elbows, tees, and crosses to ensure firm connections between components. For example, the railing system in a large shopping center used professional tools during connector installation to ensure each connector was firm and reliable.

Installing Decorative Elements: Install decorative elements such as end caps and decorative balls to enhance overall aesthetics. For instance, the handrail system in a luxury hotel underwent meticulous processing during decorative element installation to ensure each decorative element was flawless.

Inspection and Adjustment

Overall Inspection: Inspect the overall stability and aesthetics of the railing and handrail system to ensure no looseness or deviation. For example, the handrail system in a high-rise residential building underwent a comprehensive inspection after installation to ensure every detail met design requirements.

Detail Adjustment: Adjust the details to ensure all connectors and decorative elements are installed in place. For instance, the handrail system in a commercial building underwent multiple detail adjustments after installation to ensure each connector and decorative element was perfectly aligned.

Maintenance and Care

Regular Cleaning

Cleaning Method: Use a neutral cleaner and a soft cloth to wipe the stainless steel surface, avoiding cleaners containing chlorine. For example, the handrail system in a shopping center regularly uses professional cleaners to keep the surface shiny and new.

Cleaning Frequency: Clean regularly based on the usage environment and frequency to maintain the stainless steel surface's shine. For instance, the handrail system in a public facility undergoes a comprehensive cleaning every month to ensure long-term aesthetics.

Rust Prevention

Applying Rust Prevention Oil: For stainless steel tubes exposed to harsh environments, apply rust prevention oil regularly to extend their lifespan. For example, the railing system in a seaside resort undergoes rust prevention treatment every quarter to ensure long-term durability.

Rust Inspection: Regularly inspect the stainless steel tubes for rust and address any rust spots promptly. For instance, the handrail system in a chemical plant undergoes rust inspection every six months to ensure system safety and durability.

Fastener Inspection

Tightening Screws: Regularly check the tightness of screws and nuts to prevent loosening. For example, the handrail system in a large shopping center undergoes fastener inspection every quarter to ensure system stability.

Weld Inspection: Inspect the firmness of welds to prevent cracking or detachment. For instance, the railing system in a public square undergoes weld inspection every year to ensure system safety.

Conclusion

The application of stainless steel tubes in railing and handrail systems not only enhances the system's aesthetics and safety but also provides excellent corrosion resistance and durability. From design to installation, every step requires careful planning and execution to ensure the final result meets expectations. As a manufacturer of stainless steel tubes, we are committed to providing high-quality products and professional services to help customers achieve the best railing and handrail system solutions.

Customer Cases

High-End Apartment Project:

We provided a stainless steel tube railing and handrail system for a high-end apartment project, using 304 stainless steel and mirror polishing, whichwas both aesthetically pleasing and durable, receiving high praise from the client.

Large Shopping Center:

In a large shopping center project, we supplied high-strength stainless steel tubes and accessories, ensuring the stability and safety of the railing system, earning the trust of the client.

Seaside Resort:

We provided a 316 stainless steel tube railing system for a seaside resort, capable of withstanding long-term salt corrosion, ensuring the durability and aesthetics of the system.

Contact Us

If you are interested in our stainless steel tube products or have any questions, please feel free to contact us. We are dedicated to providing professional consultation and services to help you achieve the best railing and handrail system solutions.